Metal Bellow Seals are widely used in high temperature and highly corrosive media and suitable for high start-up torque since the bellows unit is independent of torque transmission.

The unique feature of Welded Metal Bellow Mechanical Seals is that, there is no dynamic O-rings and therefore it will never hang up or damage the shaft and sleeve.

A bellow core constructed by welding number of metal diaphragms together eliminates the need for springs, providing more flexibility to the seal face compensating for seal face wear.

Advantages

Uniform plate rigidity and stress distribution

Enhanced fatigue strength

Pressure-balanced by design

Less heat generated

Lower power consumption

Material

Rotary Ring (SiC/Carbon/TC)

Stationary Ring (SiC/TC)

Secondary Seal (VITON/Encapsulated Ring/PTFE)

Metal Bellows (SUS316L/AM350/Inconel718/Titanium/Hastelloy-C/AIIoy-20)

Other Parts (SUS304/SUS316/Titanium/Hastelloy-C)

Recommended applications

Generally used for handling highly corrosive chemicals, high temperature applications and Hydrocarbons In Petrochemical industry, petroleum refinery , Paper & Pulp industry

Operating Limits

Pressure: ≤2.1MPa

Speed: ≤20m/s

Temperature: -20℃~+200℃

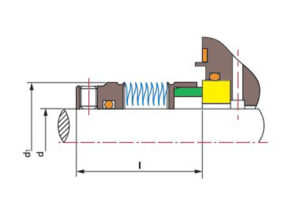

| Seal size | d1 | l |

| d(inches) | ||

| 0.75 | 1.312 | 1.25 |

| 0.875 | 1.437 | 1.25 |

| 0.937 | 1.5 | 1.25 |

| 1 | 1.562 | 1.25 |

| 1.125 | 1.687 | 1.25 |

| 1.25 | 1.812 | 1.312 |

| 1.375 | 1.937 | 1.437 |

| 1.5 | 2.062 | 1.437 |

| 1.625 | 2.187 | 1.437 |

| 1.75 | 2.312 | 1.437 |

| 1.875 | 2.437 | 1.5 |

| 2 | 2.562 | 1.5 |

| 2.125 | 2.687 | 1.5 |

| 2.25 | 2.812 | 1.562 |

| 2.375 | 2.937 | 1.562 |

| 2.5 | 3.187 | 1.562 |

| 2.625 | 3.312 | 1.625 |

| 2.75 | 3.437 | 1.625 |

| 2.875 | 3.625 | 1.687 |

| 3 | 3.75 | 1.687 |

| 3.125 | 3.875 | 1.75 |

| 3.25 | 4 | 1.75 |

| 3.375 | 4.125 | 1.75 |

| 3.5 | 4.25 | 1.875 |

| 3.625 | 4.375 | 1.875 |

| 3.75 | 4.5 | 1.875 |

| 3.875 | 4.625 | 1.875 |

| 4 | 4.75 | 1.875 |

| 4.25 | 5.187 | 1.903 |

| 4.5 | 5.437 | 1.903 |

| 4.75 | 5.687 | 1.903 |

| 5 | 5.937 | 1.903 |

| 5.25 | 6.213 | 1.903 |

| 5.5 | 6.463 | 1.903 |

| 5.75 | 6.714 | 1.903 |

| 6 | 6.964 | 1.903 |

| Seal size | d1 | l |

| d(mm) | ||

| 18 | 32 | 27.5 |

| 20 | 33.3 | 27.5 |

| 22 | 36 | 27.5 |

| 24 | 38.1 | 30 |

| 25 | 39 | 30 |

| 28 | 42 | 32.5 |

| 30 | 44 | 32.5 |

| 32 | 46 | 32.5 |

| 33 | 47 | 32.5 |

| 35 | 49.2 | 32.5 |

| 38 | 52.4 | 34 |

| 40 | 55.6 | 34 |

| 43 | 58.7 | 34 |

| 45 | 58.7 | 34 |

| 48 | 61.9 | 34 |

| 50 | 65.1 | 34.5 |

| 53 | 68.3 | 34.5 |

| 55 | 71 | 34.5 |

| 60 | 74.6 | 39.5 |

| 65 | 84.1 | 39.5 |

| 70 | 87.3 | 45 |

| 75 | 95.3 | 45 |

| 80 | 98.4 | 44.5 |

| 85 | 104.8 | 44.5 |

| 90 | 108 | 49.5 |

| 95 | 114.3 | 49.5 |

| 100 | 120.7 | 49.5 |

| 105 | 131.7 | 48.3 |

| 110 | 138.1 | 48.3 |

| 115 | 144.5 | 48.3 |

| 120 | 144.5 | 48.3 |

| 125 | 150.8 | 48.3 |

| 130 | 157.8 | 48.3 |

| 140 | 170.5 | 48.3 |

| 150 | 176.9 | 48.3 |