There are four aspects to be considered when selecting the proper gasketing material:

With the diversity of gasket materials available in the market sometimes it becomes an issue to find the correct one for your application; do not run any risk and in case of doubt contact us,we are willing to assist.

Having problems with your gaskets?

Why not give us a call on APEX SEALING TECHNOLOGIES PTE LTD @ sales@apexsealing.com.sg / marketing@apexsealing.com.sg

Tel: +65 62650768 Fax: +65 62653498

APEX sealing Technologies believe in environmentally friendly and reliable applications. It strives to capture all industries by servicing and supplying certified products with recognized certificates.

You can count on us when sealing solution is concerned. We understand your problem and recommended the solutions.

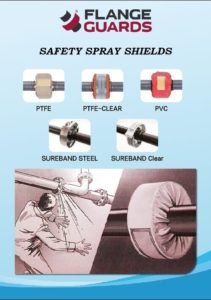

Safety spray shields, also known as flange guards are used in a variety of industries, where their primary applications is the prevention of harmful spray-outs and mist formation from failing pipe joints, of toxic, corrosive and dangerous liquids such as acid, oil or steam.

Safety spray shields offer the last line of defence. They are not designed to contain the leak indefinitely,but to prevent the harmful spray outs resulting in fire or explosions causing considerable plant down time,capital expenditure and even loss of fire .

Safety shields are made to fit specific flange & fitting sizes. As such, for retrofits, the next step is to perform a site survey. This is not rocket science, but it is important to get right first time. Hence, Apex do provide on-site services as below, to assist our client to get the right products installed on their flange and valves:

Apex will send a professional engineer on-site to survey the flange and valves and obtain the required sizes for each safety shields.

Measuring a flange is easy enough but fitting a box full of shields is impossible if clients do not know where they are supposed to go. Our engineer can survey the specific areas and pipe-runs within the plant and make plan for clients if the pipe-runs are complex.

Our engineer will go on-site to install the shield in most effective way if the service is requested by client.

We are able to provide customized Insulation Lagging that are suitable for high temperature

& on steam pipe. We can do onsite inspection and measurements.

Mechanical Seals are leakage control devices, which are found on rotating equipment such as pumps and mixers to prevent the leakage of liquids and gases from escaping into the environment.

A mechanical seal consists of 2 principle components. One component is stationary and the other rotates against it to achieve a seal. There are many types of mechanical seal, ranging from simple single spring designs to considerably more complex cartridge seal types. The design, arrangement and materials of construction are essentially determined by the pressure, temperature, speed of rotation and product being sealed.

We are able to provide recondition service.

We are able to provide installation service of refractory products in heavy industries.

We pride ourselves in providing products and services to the offshore projects in a multitude of industries.