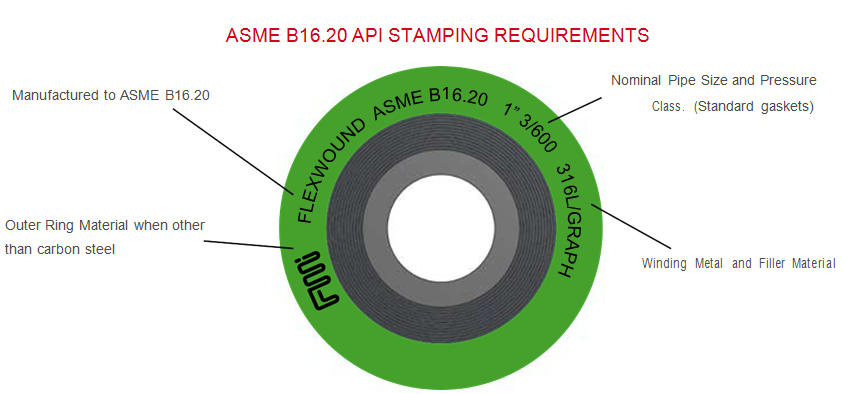

SPIRAL WOUND GASKETS FLEXWOUND ®

DESCRIPTION:

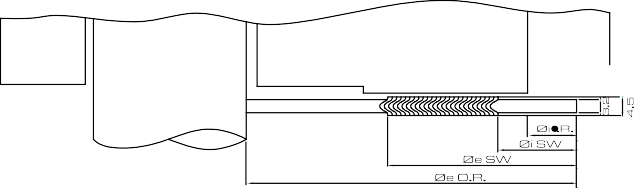

Gasket made from spiral of metal material (strip) and non metal material (filler). SWG can have outer and inner rings.

Spiral wound gaskets are capable of meeting the most exacting condition of pressure and temperature.

TYPE:

GRI

| The standard version is the Style GRI spiral wound gasket with inner and outer ring. This gasket has the best sealing characteristics combined with the highest safety for flanged joints with flat face and raised face flanges. |

GR

| By means of suitable dimensioning of the centering ring, the sealing element is accurately centered on the flange face by the bolts. A general purpose gasket for use with flat face and raised face flanges. |

RR

| Style RR spiral wound gasket with no accessory ring is suitable for tongue and groove applications and for operation with a compression stop. Given a gasket thickness of 4.5 mm, a groove depth of 3.3 (± 0.1) mm is recommended to provide the compression stop. |

RI

| Style RI spiral wound gasket with inner ring is designed specifically for male and female flanges, the inner ring providing radial confinement to prevent blow-out of the spiral element. |

Available several materials for the spiral and for the rings.

Standard materials:

| METAL WINDING STRIP | FILLER MATERIAL | GUIDE RING MATERIAL |

| SS316L | Graphite | Carbon steel |

| SS304 |

Other materials:

| METAL WINDING STRIP | FILLER MATERIAL | GUIDE RING MATERIAL |

| SS304L | Micatherm | SS316L |

| SS309 | Sichem | SS304 |

| SS310 | PTFE | SS304L |

| SS316TI | BIOCERAMIC | SS309 |

| SS321 | SS310 | |

| SS347 | SS316TI | |

| SS430 | SS321 | |

| SS410 | SS347 | |

| ALLOY 20 | SS430 | |

| MONEL | SS410 | |

| TITANIUM | ALLOY 20 | |

| NICKEL | MONEL | |

| INCONEL 600 | TITANIUM | |

| INCONEL 625 | NICKEL | |

| INCONEL X-750 | INCONEL 600 | |

| HASTELLOY B2 | INCONEL 625 | |

| HASTELLOY C276 | INCONEL X-750 | |

| INCOLOY 800 | HASTELLOY B2 | |

| INCOLOY 825 | HASTELLOY C276 | |

| DUPLEX | INCOLOY 800 | |

| SUPER DUPLEX | INCOLOY 825 | |

| ZIRCONIUM | DUPLEX | |

| TANTALUM | SUPER DUPLEX | |

| COPPER | ZIRCONIUM | |

| PHOS-BRONZE | TANTALUM | |

| CARBON STEEL | COPPER | |

| PHOS-BRONZE | ||

| CARBON STEEL |

APPROVAL:

VDI 2440-EMISSION CONTROL

COLOR:

For ease identification, we utilize a color coding system around the outside of the centering ring, thus permitting full identification of both the widing and filler materials.

TECHNICAL INFORMATIONS:

High temperatures and high pressures depending from selected materials.

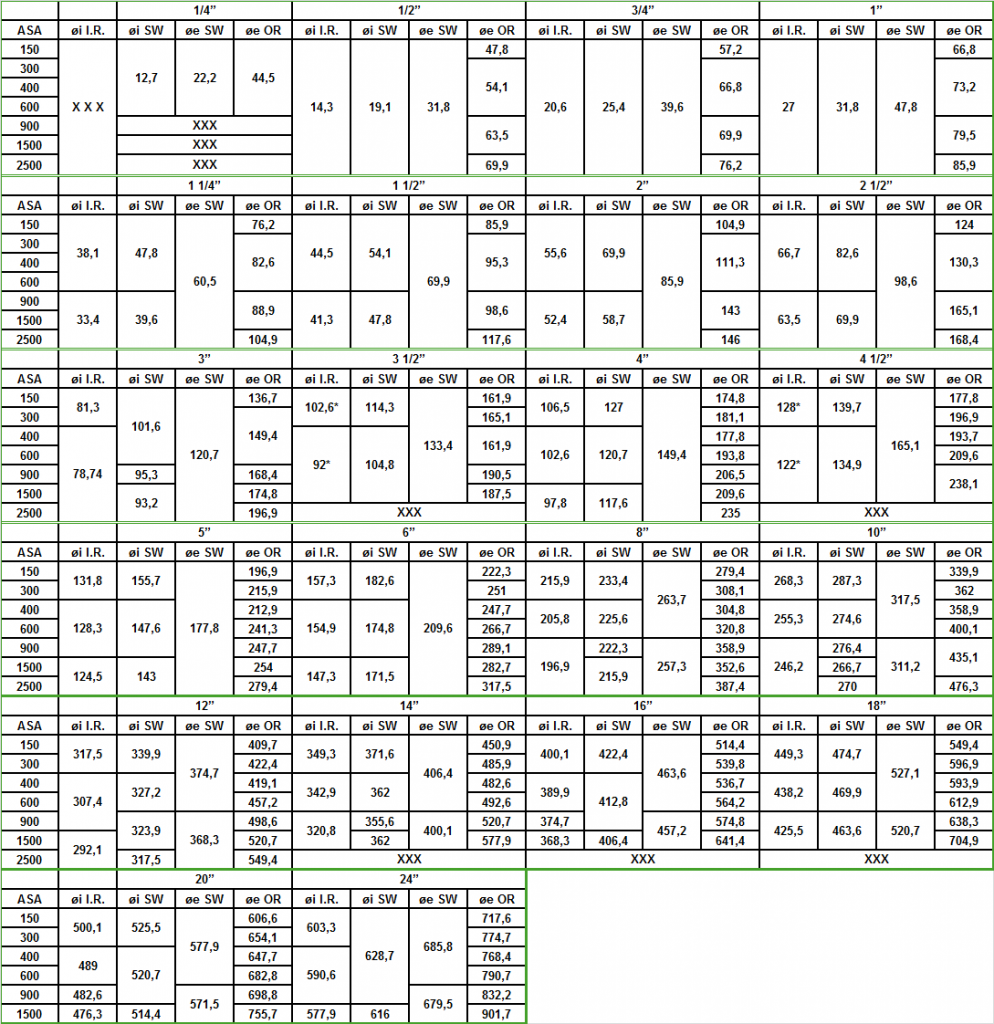

DIMENSIONAL DATA STYLE GR AND GRI TO ASME B16.20 TO SUIT ASME B16.5 FLANGES

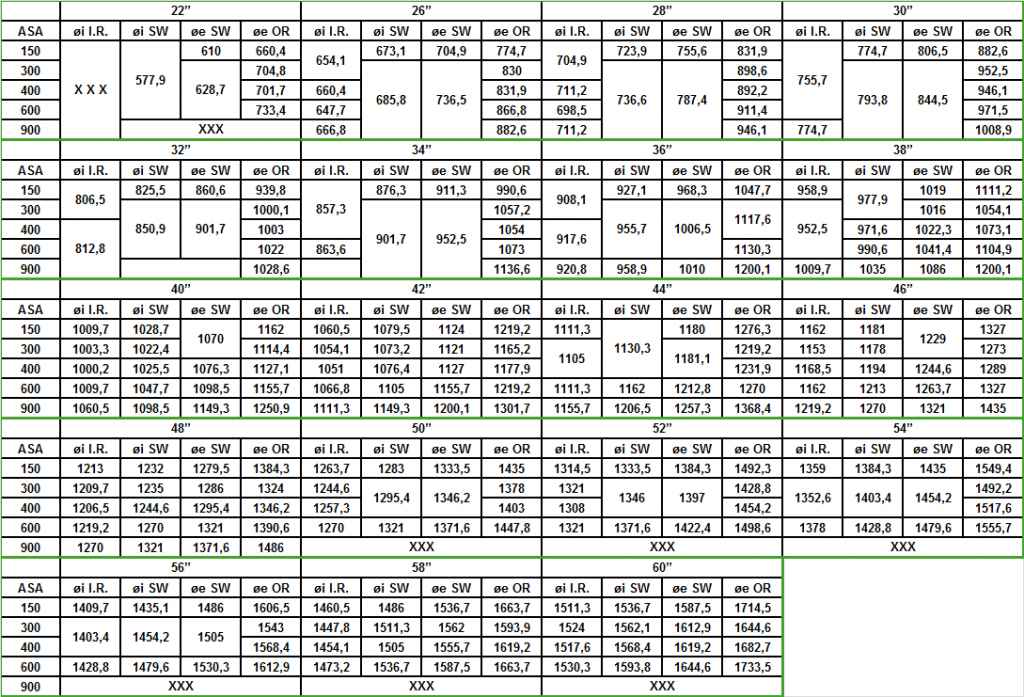

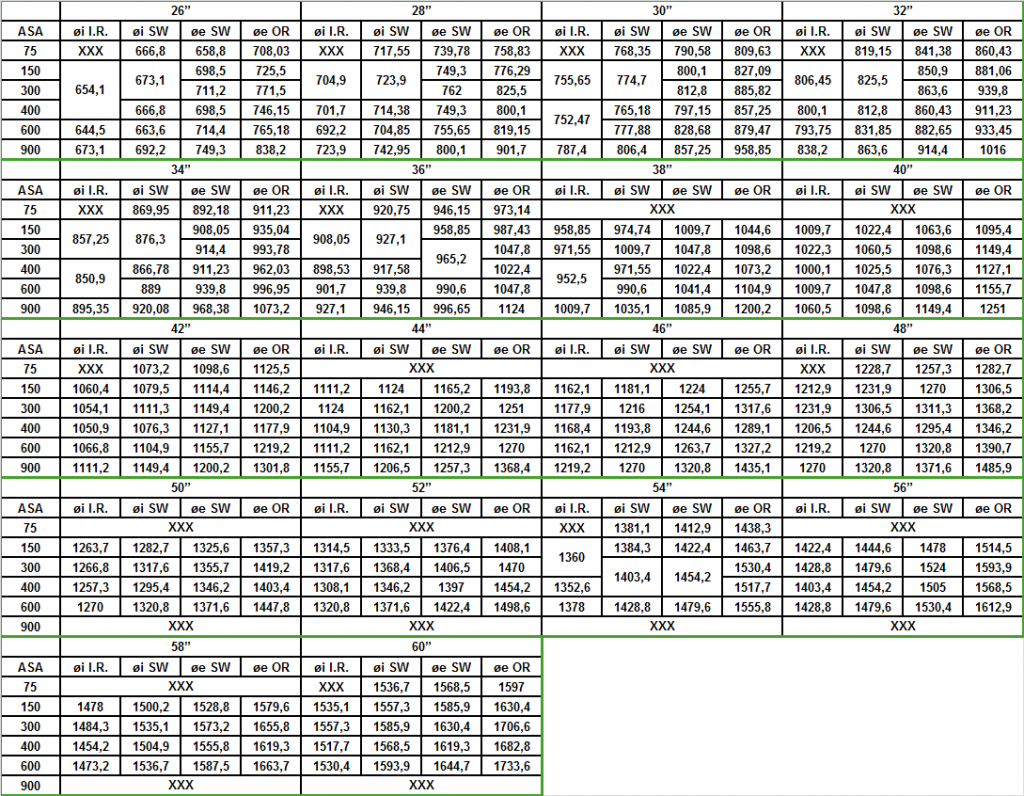

DIMENSIONAL DATA STYLE GR AND GRI T O ASME B16.20 TO SUIT ASME B16.47 SERIES A FLANGES

DIMENSIONAL DATA STYLE GR AND GRI TO ASME B16.20 T O SUIT ASME B16.47 SERIES B FLANGES

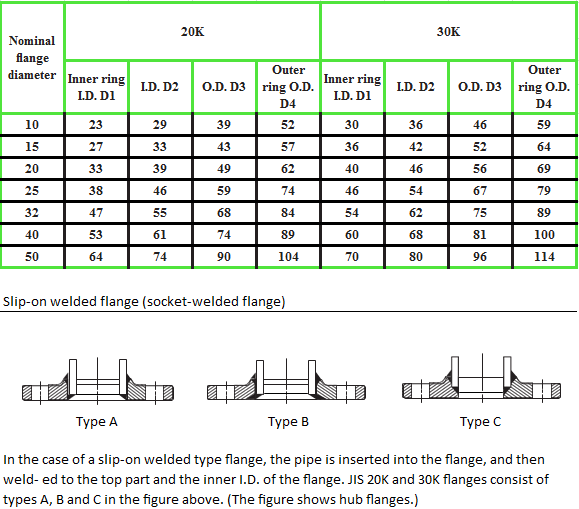

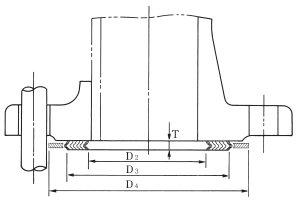

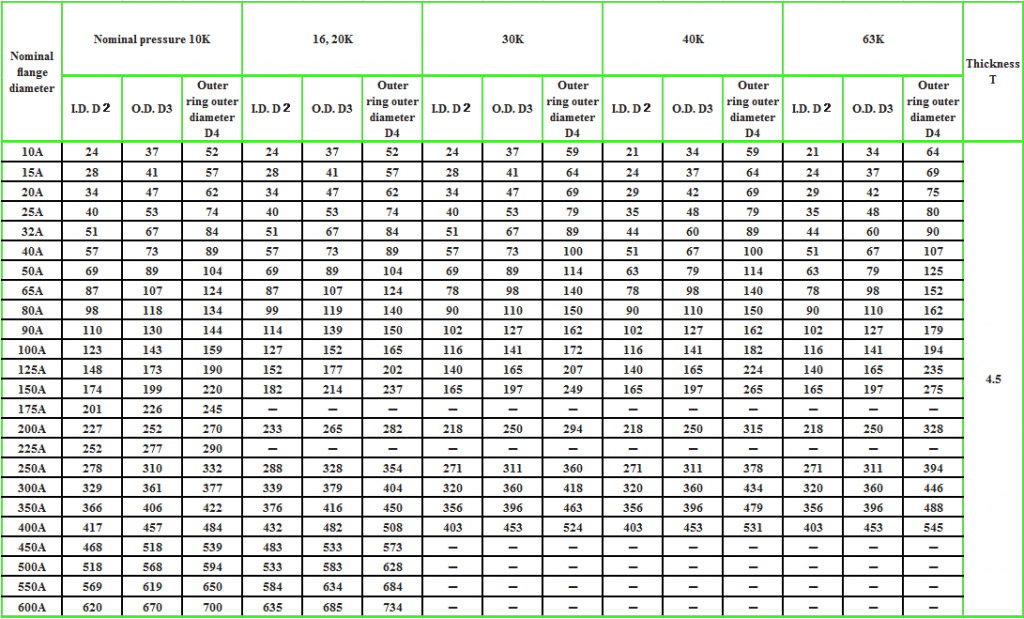

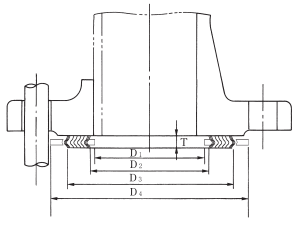

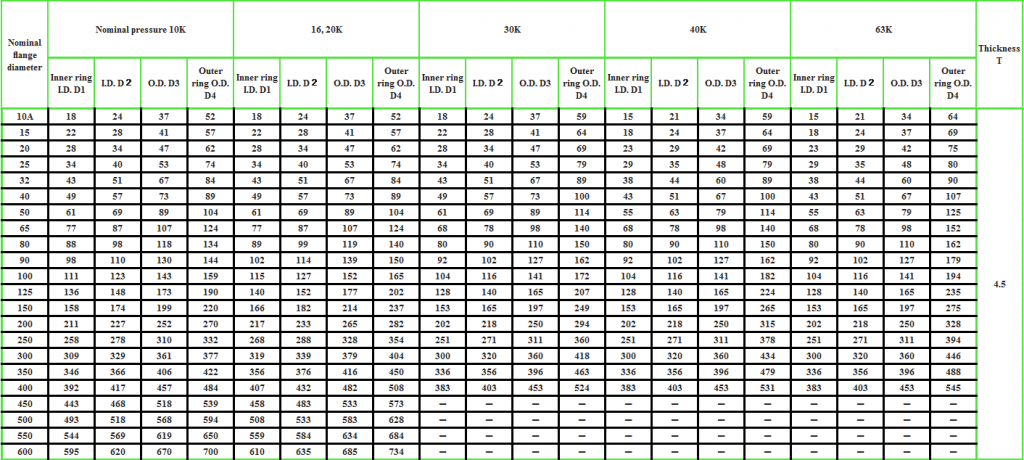

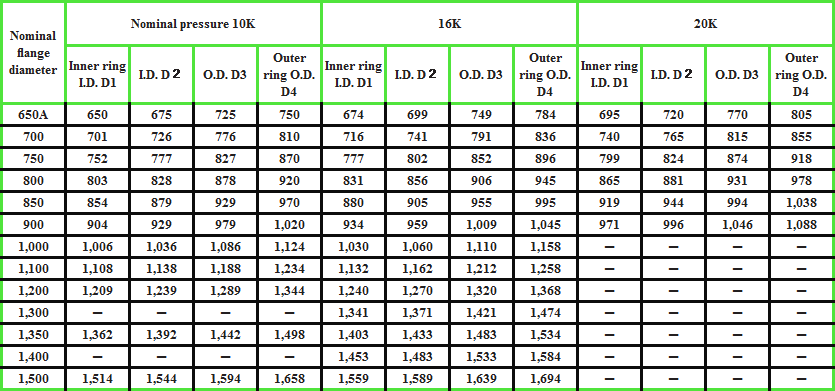

DIMENSIONAL DATA STYLE GR TO JIS B 2404-2006 TO SUIT JIS B 2220-2004/JIS B 2239-1996 FLANGES

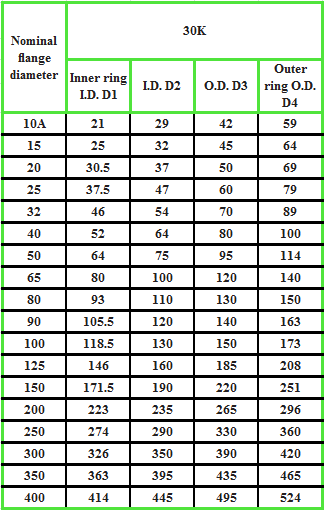

DIMENSIONAL DATA STYLE GRI TO JIS B 2404-2006 TO SUIT JIS B 2220-2004/JIS B 2239-1996 FLANGES

Unit (mm)

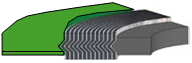

The dimensions in the double border cannot be used on small flat seats.

The dimensions in the bold border apply to large flat seats and small flat seats. (Note, however, that these dimensions apply only to butt-welded flanges and type C slip-on welded flanges stipulated in JIS B 2220.)

For a 30K type A slip-on welded flange and a type B slip-on welded flange, use the dimensions on Page 80.

It is recommended that gaskets with inner and outer rings be used on flanges that are intended for a nominal pressure of 63K.

It is recommended that fitted with inner and outer rings.

It is not recommended that gaskets used on flanges intended for nominal pressures 2K and 5K.

It is recommended that high-strength alloy steel bolts of SNB-7 or higher to be used

For type A slip-on welded flanges (socket- welded type)

For type B slip-on welded flanges (socket-welded type)