RING JOINT GASKETS

RTJ gaskets are produced in different solid metal types. They are used for high pressure (till 1300 bar) and for high temperature (till 1000°C) and are used where corrosive agents are presents. These gaskets are obtained by mechanical working from forged or laminated metals. RTJ find their mainly application in refining process in crude extraction and in high pressure applications. For their production we use the last edition of the API standard. FMI can supply oval and octagonal ring joint, BX and RX for all applications to suite the flanges design with standard and special styles.

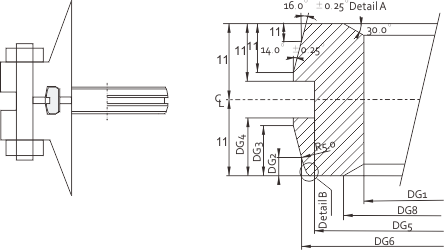

IX Type Gasket

TABLE B.2-DIMENSIONS OF IX SEAL RINGS AND THEIR WEIGHTS

| DN | NPS | IX

size |

Dg1

mm |

DG2

mm |

DG3

mm |

DG4

mm |

DG5

mm |

DG6

mm |

DG7

mm |

DG8

mm |

HG1

mm |

HG2

mm |

HG3

mm |

HG4

mm |

HG5

mm |

RG1

mm |

Weight

kg |

| 15 | 1/2 | IX15 | 22.2 | 27.91 | 28.46 | 28.66 | 27.47 | 29.14 | 30.19 | 24.7 | 0.35 | 1.20 | 3.30 | 3.8 | 10.00 | 0.5 | 0.02 |

| 20 | 3/4 | IX20 | 27.2 | 32.93 | 33.47 | 33.67 | 32.48 | 34.16 | 35.20 | 29.7 | 0.35 | 1.20 | 3.30 | 3.8 | 10.00 | 0.5 | 0.03 |

| 25 | 1 | IX25 | 34.2 | 39.95 | 40.49 | 40.69 | 39.50 | 41.18 | 42.22 | 36.7 | 0.35 | 1.20 | 3.30 | 3.8 | 10.00 | 0.5 | 0.03 |

| 40 | 1 1/2 | IX40 | 49.3 | 55.84 | 56.38 | 56.58 | 55.34 | 57.11 | 58.21 | 51.9 | 0.35 | 1.27 | 3.48 | 4.0 | 10.56 | 0.5 | 0.05 |

| 50 | 2 | IX50 | 61.3 | 68.43 | 69.08 | 69.32 | 67.92 | 69.89 | 71.13 | 64.4 | 0.42 | 1.41 | 3.89 | 4.5 | 11.78 | 0.6 | 0.08 |

| 65 | 2 1/2 | IX65 | 74.4 | 82.14 | 82.79 | 83.03 | 81.52 | 83.69 | 85.05 | 77.8 | 0.42 | 1.56 | 4.28 | 4.9 | 12.98 | 0.6 | 0.12 |

| 80 | 3 | IX80 | 89.5 | 97.74 | 98.49 | 98.77 | 97.09 | 99.47 | 100.96 | 93.3 | 0.49 | 1.71 | 4.70 | 5.4 | 14.24 | 0.7 | 0.17 |

| 100 | 4 | IX100 | 115.7 | 125.17 | 126.04 | 126.36 | 124.44 | 127.15 | 128.85 | 120.1 | 0.56 | 1.94 | 5.34 | 6.2 | 16.19 | 0.8 | 0.28 |

| 125 | 5 | IX125 | 142.0 | 152.66 | 153.64 | 154.00 | 151.87 | 154.87 | 156.75 | 146.7 | 0.63 | 2.15 | 5.92 | 6.8 | 17.94 | 0.9 | 0.42 |

| 150 | 6 | IX150 | 170.2 | 182.17 | 183.25 | 183.66 | 181.32 | 184.61 | 186.66 | 175.4 | 0.70 | 2.36 | 6.48 | 7.5 | 19.64 | 1.0 | 0.62 |

| 200 | 8 | IX200 | 220.5 | 233.46 | 234.66 | 235.10 | 232.45 | 236.19 | 238.54 | 226.5 | 0.77 | 2.68 | 7.38 | 8.5 | 22.36 | 1.1 | 0.99 |

| 250 | 10 | IX250 | 274.9 | 292.64 | 294.05 | 294.57 | 291.57 | 295.78 | 298.42 | 281.7 | 0.91 | 3.02 | 8.31 | 9.6 | 25.20 | 1.3 | 1.85 |

| 300 | 12 | IX300 | 325.0 | 341.13 | 342.65 | 343.21 | 339.97 | 344.52 | 347.36 | 332.5 | 0.98 | 3.26 | 8.96 | 10.4 | 27.15 | 1.4 | 2.18 |

| 350 | 14 | IX350 | 357.1 | 373.87 | 375.38 | 375.94 | 372.58 | 377.34 | 380.32 | 365.0 | 0.98 | 3.42 | 9.39 | 11.0 | 28.46 | 1.4 | 2.60 |

| 400 | 16 | IX400 | 409.3 | 427.36 | 428.98 | 429.58 | 425.98 | 431.08 | 434.27 | 417.9 | 1.05 | 3.66 | 10.05 | 11.9 | 30.47 | 1.5 | 3.43 |

| 450 | 18 | IX450 | 459.4 | 478.90 | 480.63 | 481.27 | 477.45 | 482.85 | 486.23 | 468.6 | 1.12 | 3.87 | 10.65 | 12.7 | 32.28 | 1.6 | 4.38 |

| 500 | 20 | IX500 | 511.6 | 531.45 | 533.29 | 533.97 | 529.93 | 535.63 | 539.20 | 521.4 | 1.19 | 4.09 | 11.24 | 13.5 | 34.06 | 1.7 | 5.27 |

| 550 | 22 | IX550 | 561.7 | 583.04 | 584.99 | 585.71 | 581.62 | 587.44 | 591.18 | 572.1 | 1.26 | 4.28 | 11.78 | 14.3 | 35.69 | 1.8 | 6.48 |

| 600 | 24 | IX600 | 611.9 | 633.64 | 635.70 | 636.46 | 632.40 | 638.26 | 642.16 | 622.8 | 1.33 | 4.47 | 12.29 | 15.0 | 37.25 | 1.9 | 7.55 |

| 650 | 26 | IX650 | 664.0 | 686.37 | 688.42 | 689.18 | 685.19 | 691.09 | 695.16 | 675.5 | 1.33 | 4.66 | 12.81 | 15.7 | 38.81 | 1.9 | 8.74 |

| 700 | 28 | IX700 | 714.1 | 738.01 | 740.17 | 740.97 | 737.01 | 742.94 | 747.16 | 726.1 | 1.40 | 4.83 | 13.28 | 16.3 | 40.25 | 2.0 | 10.4 |

| 750 | 30 | IX750 | 766.3 | 790.65 | 792.92 | 793.77 | 789.83 | 795.79 | 800.16 | 778.8 | 1.47 | 5.00 | 13.76 | 17.0 | 41.69 | 2.1 | 11.8 |

| 800 | 32 | IX800 | 816.4 | 841.32 | 843.70 | 844.58 | 840.67 | 846.66 | 851.16 | 829.4 | 1.54 | 5.16 | 14.20 | 17.6 | 43.03 | 2.2 | 13.3 |

| 850 | 34 | IX850 | 866.6 | 892.10 | 894.48 | 895.36 | 891.52 | 897.53 | 902.18 | 879.9 | 1.54 | 5.32 | 14.63 | 18.2 | 44.34 | 2.2 | 14.8 |

| 900 | 36 | IX900 | 918.7 | 945.78 | 948.27 | 949.19 | 945.38 | 951.41 | 956.19 | 932.6 | 1.61 | 5.48 | 15.06 | 18.8 | 45.65 | 2.3 | 17.1 |

| 950 | 38 | IX950 | 968.8 | 996.59 | 999.08 | 1000.00 | 996.26 | 1002.30 | 1007.21 | 983.1 | 1.61 | 5.63 | 15.47 | 19.3 | 46.88 | 2.3 | 18.9 |

| 1000 | 40 | IX1000 | 1021.0 | 1049.28 | 1051.88 | 1052.85 | 1049.13 | 1055.19 | 1060.23 | 1035.7 | 1.68 | 5.77 | 15.88 | 19.9 | 48.12 | 2.4 | 20.9 |

| 1050 | 42 | IX1050 | 1071.1 | 1100.00 | 1102.70 | 1103.71 | 1100.02 | 1106.10 | 1111.26 | 1086.2 | 1.75 | 5.92 | 16.27 | 20.4 | 49.29 | 2.5 | 23.0 |

| 1100 | 44 | IX1100 | 1121.3 | 1150.83 | 1153.53 | 1154.54 | 1150.92 | 1157.00 | 1162.28 | 1136.8 | 1.75 | 6.05 | 16.64 | 21.0 | 50.43 | 2.5 | 25.1 |

| 1150 | 46 | IX1150 | 1173.4 | 1203.55 | 1206.36 | 1207.40 | 1203.82 | 1209.91 | 1251.31 | 1189.3 | 1.82 | 6.19 | 17.03 | 21.5 | 51.59 | 2.6 | 27.5 |

| 1200 | 48 | IX1200 | 1223.6 | 1254.39 | 1257.20 | 1257.25 | 1254.73 | 1260.83 | 1266.35 | 1239.8 | 1.82 | 6.32 | 17.39 | 22.0 | 52.68 | 2.6 | 29.9 |