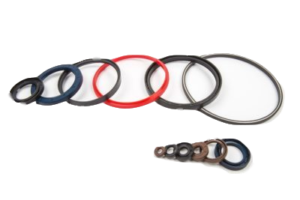

Oil seal also described as a rotary oil seal, shaft seal or lip seal. Oil seals are used between rotating and stationary machine components or between two components in relative motion and consist of two main parts:

Some shaft seal designs have an auxiliary lip that protects the primary sealing lip from dust and other contaminants. A suitable lubricant in the space between the primary sealing lip and the auxiliary lip can reduce wear and delay corrosion. Contaminants that have passed the auxiliary lip will eventually cause damage in the counter face surface area. A build-up of heat can also occur between the two lips, resulting in premature wear.

Oil seals are used in a multitude of applications. Because of the importance of radial shaft seals for the operational reliability and service life of machines and equipment, both seal manufacturers and users are equally interested, to some degree, in standardization. This has led to the establishment of national and international standards and guidelines listed in the table. These cover boundary dimensions, tolerances, material specifications, test methods and terminology as well as the basic outside diameter constructions and sealing lip arrangements.

The terminology used in this chapter is listed for metal-cased seal and for rubber outside diameter seal.

Material grade of Oil Seal: